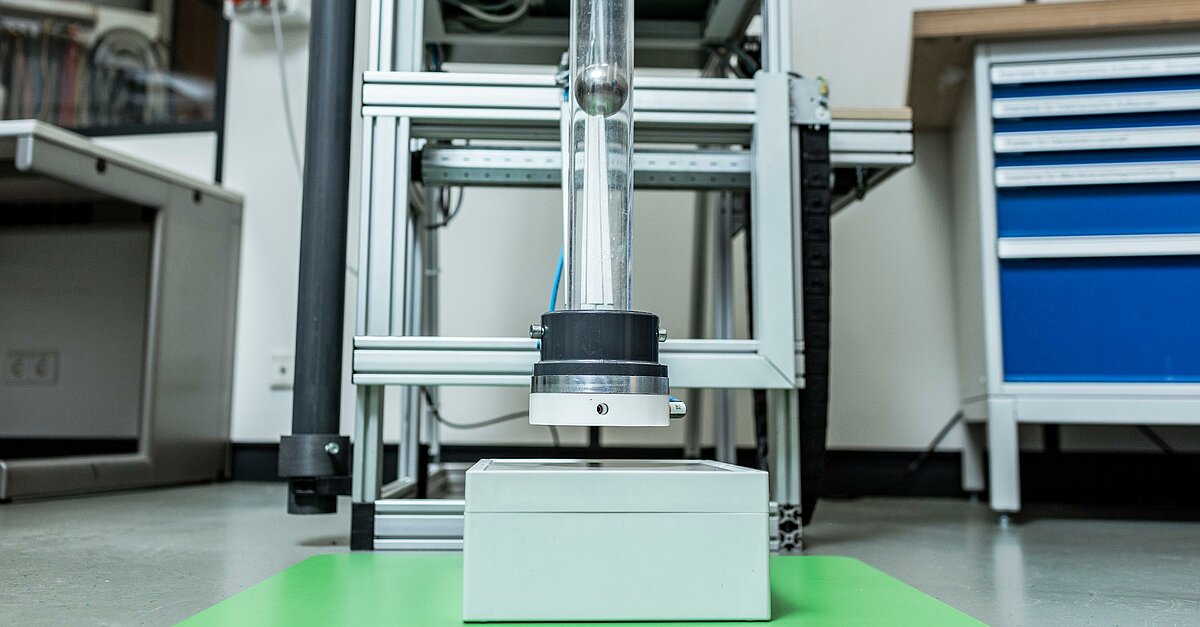

As preparation for the test for verification against mechanical stress in accordance with UL 746C, the operating equipment for outdoor use must first be cooled in a cold chamber for three hours at a temperature of -35 (± 2°C) and then mounted on a rigid frame corresponding to the planned use. Then a single strike with a steel ball with a diameter of 50.8 mm (2 inches) and weight of 0.535 kg (1.18 lbs) is exerted on the surface to be tested in the cold state.

The test specimen must not have any damage that can impair the proper use after the testing process. Moreover, the planned protection rating must not be changed negatively.