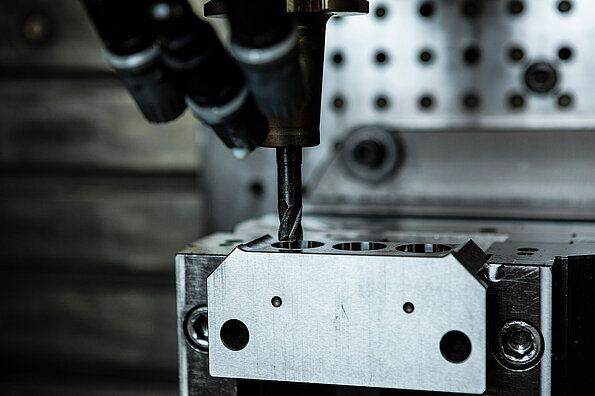

The entire customising process from the idea to the certified serial model runs through the main Spelsberg factory in Schalksmühle. In this manner, collaboration between the individual experts and departments is greatly simplified. This enables perfect intermeshing of the individual work steps like gears in a motor. This assures the best results in the shortest time.

At the beginning of each project, the developers and customers sit down at a table to precisely define all requirements for the solution to be developed and then create an initial three-dimensional CAD model. The foundation for success is only established once all details have been worked out from the initial development stage onwards, wherein a refined product is the end result.